Cov thawv ntim yas yog nyob txhua qhov chaw ntawm lub neej, los ntawm kev ntim khoom noj mus rau cov kev daws teeb meem, qhov kev thov rau cov thawv yas txuas ntxiv mus, thiab raws li tuaj yeem pab txhawb rau kev tsim cov tshuab tsim los tsim cov ntim khoom zoo. Hauv seem tom ntej no, peb yuav saib ntau hom tshuab ntim yas thiab cov txheej txheem koom nrog hauv kev tsim cov ntim yas.

Yas thawv machinery yog hais txog cov cuab yeej tshwj xeeb uas siv los tsimcov thawv yas. Cov tshuab no suav nrog ntau yam thev naus laus zis thiab cov txheej txheem, suav nrog kev txhaj tshuaj molding, tshuab moulding, thiab thermoforming, thiab txhua txoj kev muaj nws tus kheej zoo rau ntau hom ntim yas.

1. Txhaj Moulding Tshuab

Ib txoj hauv kev zoo tshaj plaws ntawm kev tsim cov thawv yas, kev txhaj tshuaj molding yuav tsum tau yaj cov yas pellets thiab txhaj cov yas molten rau hauv pwm. Thaum cov yas tau txias thiab ua kom khov, cov pwm qhib thiab lub thawv tiav yog txhaj.

Cov yam ntxwv tseem ceeb ntawm kev txhaj tshuaj molding tshuab:

-Precision: txhaj tshuaj molding tshuab paub txog lawv lub peev xwm los tsim cov ncauj lus kom ntxaws, cov duab nyuaj nrog nruj kam rau ua.

-Speed: Txhaj tshuaj molding muaj lub sij hawm luv luv, tso cai rau ntau lawm.

-Material Versatility: Txhaj tshuaj molding tuaj yeem siv ntau yam thermoplastics, ua kom haum rau ntau yam kev siv.

Kev txhaj tshuaj molding yog qhov zoo tagnrho rau kev tsim cov ntim xws li jars, fwj thiab lwm yam kev ntim khoom nruj.

2. Tshuab Moulding Tshuab

Tshuab moulding yog lwm txoj hauv kev los uacov thawv yas, tshwj xeeb tshaj yog hollow ntim xws li fwj. Cov txheej txheem pib nrog kev tsim ntawm lub tubular yas pwm dawb paug. Lub parison yog tom qab ntawd muab tso rau hauv pwm rau hauv uas cov cua tshuab tau nthuav dav cov yas thiab tsim cov pwm pwm.

Cov yam ntxwv tseem ceeb ntawm tshuab moulding tshuab:

-High efficiency: tshuab moulding yog qhov zoo heev rau kev tsim cov ntim loj loj.

-Lightweight containers: Txoj kev no tso cai rau kev tsim cov ntim khoom hnyav, uas txo cov nqi tsheb thauj mus los thiab kev cuam tshuam ib puag ncig.

- Ntau yam ntawm cov duab: tshuab moulding tuaj yeem tsim cov ntim ntawm ntau cov duab thiab ntau thiab tsawg, los ntawm cov fwj me mus rau cov thawv ntim loj.

Tshuab moulding feem ntau yog siv los tsim lub raj mis dej haus, ntim tshuaj ntxuav tes thiab lwm yam khoom zoo sib xws.

3. Thermoforming tshuab

Thermoforming yog txheej txheem ntawm cua sov ib daim ntawv ntawm cov yas kom txog rau thaum nws yog pliable thiab ces molding nws mus rau hauv ib tug tshwj xeeb zoo uas siv lub pwm. Cov yas txias cia thiab tswj cov pwm pwm, ua rau lub thawv tiav.

Cov yam ntxwv tseem ceeb ntawm cov tshuab thermoforming:

-Cov txiaj ntsig zoo: thermoforming feem ntau yog tus nqi ntau dua li kev txhaj tshuaj molding lossis tshuab moulding thaum tsim cov ntim ntiav thiab cov tais.

-Rapid prototyping: Txoj kev no tso cai rau kev hloov pauv sai, ua rau nws tsim nyog rau kev tsim qauv thiab cov khoom me me.

-Material efficiency: Thermoforming tso cai rau kev siv cov khoom pov tseg kom zoo thiab txo cov khoom pov tseg.

Thermoforming feem ntau yog siv los tsim cov ntim khoom noj, ntim clamshell thiab cov khob pov tseg.

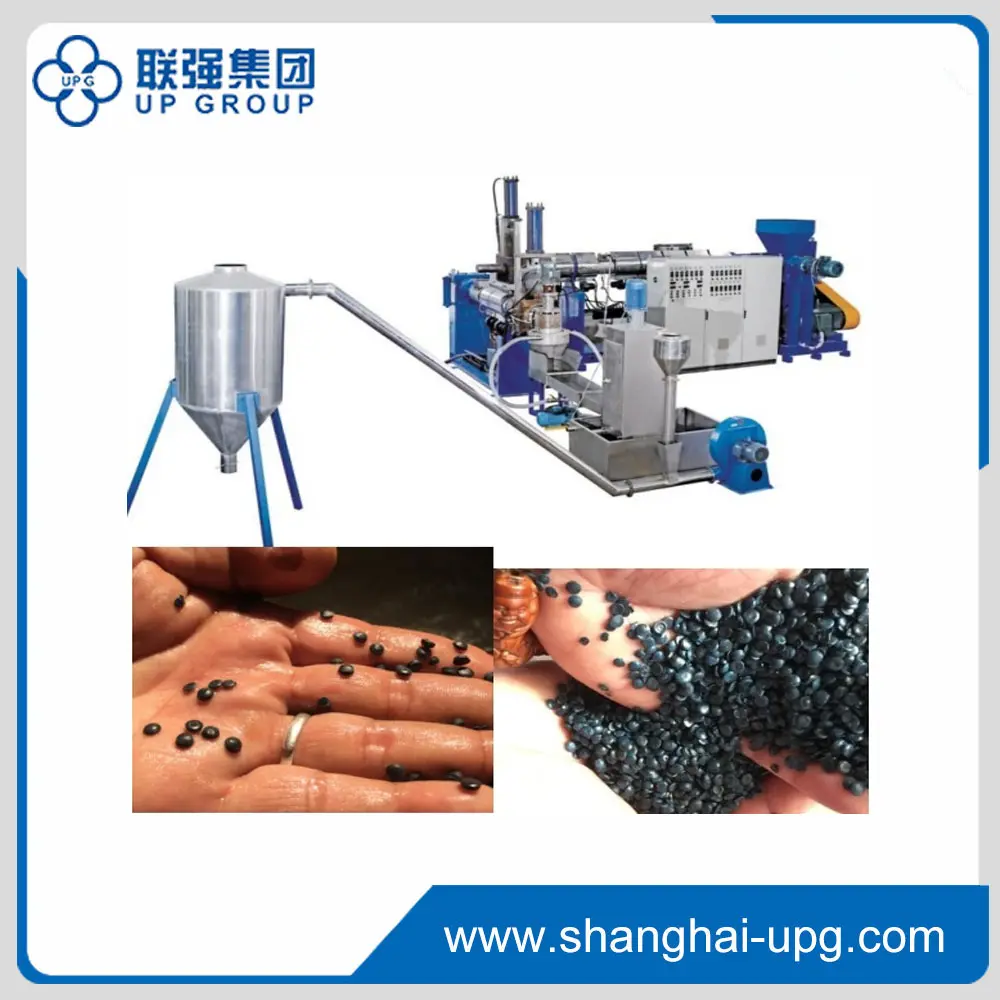

Koj tuaj yeem saib qhov no ib qho tsim los ntawm peb lub tuam txhab,LQ250-300PE Zaj duab xis Ob-theem Pelletizing Kab

Lub luag haujlwm ntawm Automation hauv Yas Thawv Machinery

Tawm tsam keeb kwm yav dhau los ntawm kev txhim kho thev naus laus zis, automation tau dhau los ua ib feem ntawm kev tsim cov thawv yas, nrog cov txheej txheem automated nce kev tsim khoom, txo cov nqi zog thiab txhim kho cov khoom sib xws. Ntau lub tshuab ntim yas niaj hnub no tau nruab nrog cov yam ntxwv siab tshaj hauv qab no:

- Kev tuav neeg hlau: Cov neeg hlau tuaj yeem thauj khoom thiab tshem tawm cov pwm tuaj yeem, ua kom nrawm thiab txo qhov kev pheej hmoo ntawm tib neeg kev ua yuam kev.

- Kev saib xyuas lub sijhawm tiag tiag: Sensors thiab software tuaj yeem saib xyuas cov txheej txheem tsim khoom hauv lub sijhawm tiag tiag kom hloov kho sai sai kom tswj tau qhov zoo.

- Kev koom ua ke nrog lwm lub tshuab: Cov cuab yeej siv tau tuaj yeem ua ke nrog kev tswj cov khoom muag thiab cov khoom siv sib txuas rau kev ua haujlwm tsis sib haum.

Environmental factors: Raws li ib puag ncig kev paub txog kev loj hlob, cov tuam ntxhab tau tsom mus rau kev ruaj khov, rov ua dua cov ntaub ntawv thiab tsim cov yas biodegradable. Kev txhim kho ntxiv ntawm cov tshuab thiab cov cuab yeej siv yuav ua rau cov txheej txheem ntau lawm, yog li txo cov khib nyiab thiab siv hluav taws xob tsawg.

Hauv kev xaus, kev tsim khoom ntawmcov thawv yastso siab rau ntau yam ntawm cov tshuab tshwj xeeb, txhua qhov tsim nyog rau cov txheej txheem ntau lawm. Kev txhaj tshuaj molding, tshuab moulding thiab thermoforming yog cov txheej txheem tseem ceeb uas siv los tsim cov khoom siv no. Automation thiab sustainability yuav ua lub luag haujlwm tseem ceeb hauv kev hloov pauv ntawm kev tsim cov thawv yas. Rau cov neeg uas tab tom nrhiav nkag mus rau hauv kev lag luam yas los yog nrhiav kev ua kom zoo tshaj qhov muaj peev xwm ntau lawm, nws yog ib qho tseem ceeb kom nkag siab txog cov tshuab thiab cov khoom siv koom nrog hauv cov txheej txheem no. Cov neeg uas xav paub yuav ua li cas ua cov thawv yas lossis xav tau los yuav lawv, thovtiv tauj peb, peb muaj cov cuab yeej technology siab heev thiab cov kws tshaj lij engineers.

Post lub sij hawm: Dec-30-2024